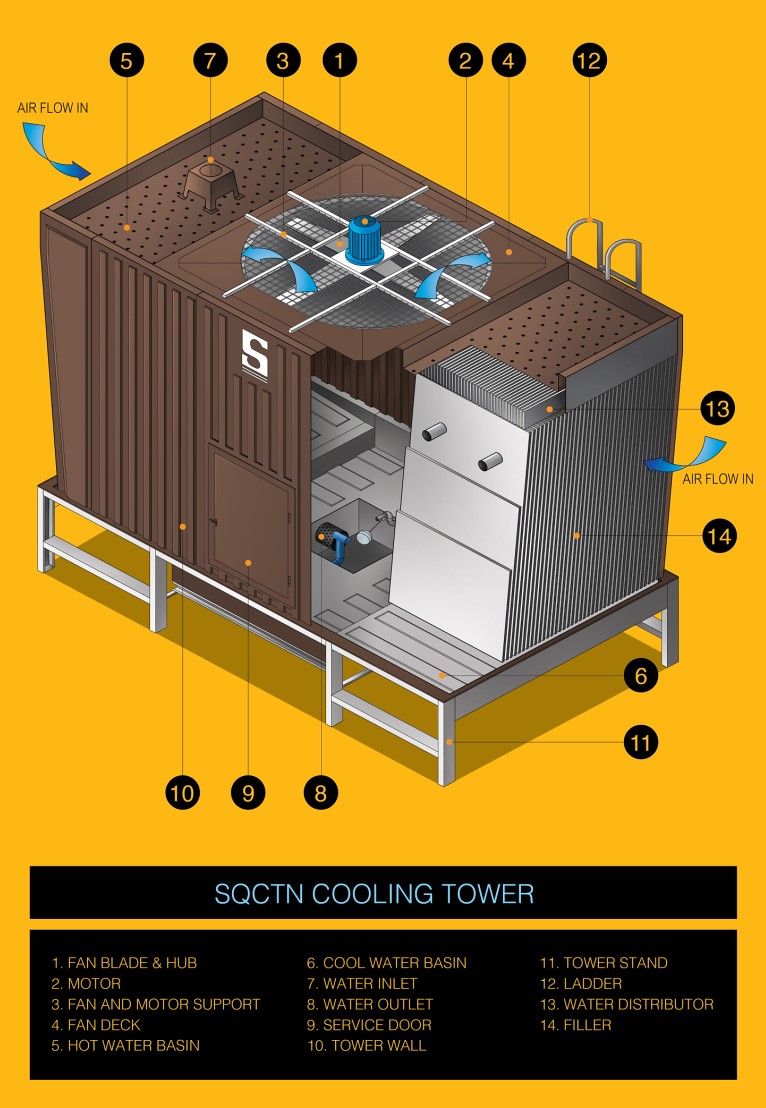

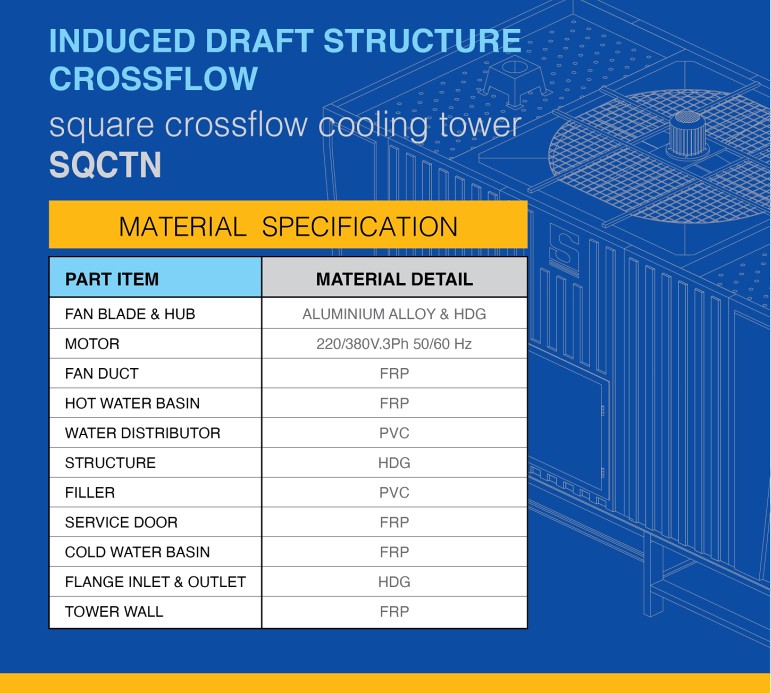

In this cooling tower system, hot water is delivered from an external source to hot water basins positioned on both sides at the top of the tower. From these basins, the water is evenly distributed over PVC fillers, which are strategically installed underneath to maximize heat exchange efficiency.

Meanwhile, cool air is drawn into the tower from the sides by a fan positioned at the top, passing through the fillers. As the hot water and cool air interact, heat transfer occurs, effectively lowering the water temperature. The cooled water then collects in the cold water basin at the bottom before being recirculated for further cooling applications. Simultaneously, hot air is expelled from the tower, ensuring continuous heat dissipation.

Key Benefits of This Cooling Tower Design

✅ Reduced Air Pressure Loss – Optimized airflow minimizes resistance, improving system efficiency.

✅ Lower Energy Consumption – The fan requires less absorbed horsepower, reducing operational costs.

✅ Efficient Heat Exchange – The structured design enhances heat dissipation, ensuring consistent cooling performance.

✅ Long-Term Durability – Utilization of high-quality PVC fillers and an advanced circulation system extends system lifespan.

✅ Lower Energy Consumption – The fan requires less absorbed horsepower, reducing operational costs.

✅ Efficient Heat Exchange – The structured design enhances heat dissipation, ensuring consistent cooling performance.

✅ Long-Term Durability – Utilization of high-quality PVC fillers and an advanced circulation system extends system lifespan.

This cost-effective and energy-efficient cooling tower solution is ideal for industries requiring reliable and consistent cooling performance while optimizing power consumption and heat transfer efficiency.

Material of Construction