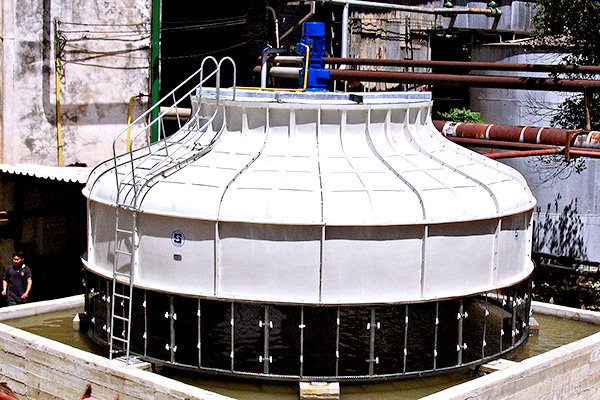

Induced Draft Counterflow Cooling Tower (Bottle Type) – Maximizing Heat Transfer Efficiency

The Counterflow Cooling Tower is one of the most efficient cooling systems, designed to enhance heat exchange between the airflow and hot water, ensuring optimal temperature reduction. This cooling tower model is widely used in industries requiring high-performance cooling solutions, such as power plants, manufacturing facilities, and large-scale HVAC systems.

How Induced Draft Counterflow Cooling Towers Work

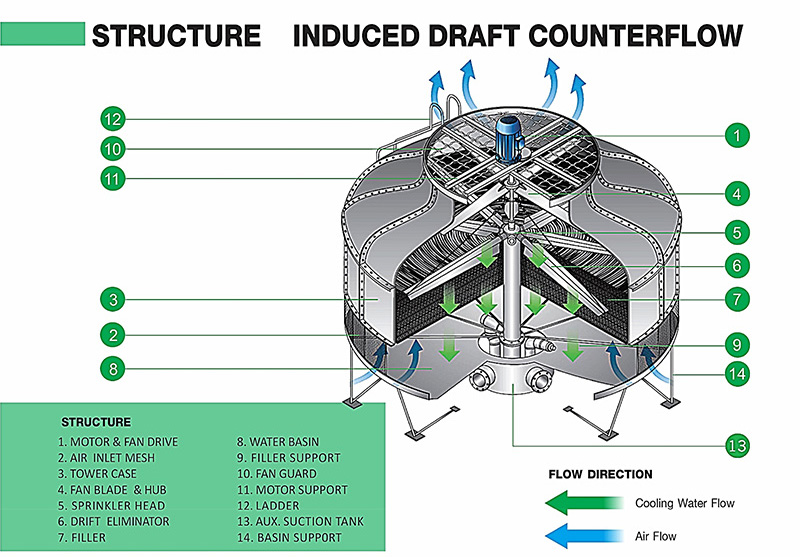

In a Counterflow Cooling Tower, hot water is distributed through sprinkler heads and sprinkler pipes, which rotate due to the water pressure supplied. The hot water then flows downward through PVC fill media (PVC Filler), creating a thin water film that increases the surface area for heat transfer.

Meanwhile, cool air from outside is drawn into the system using an axial fan installed at the top of the cooling tower. The air moves in the opposite direction of the downward-flowing hot water, enabling an efficient heat exchange process. As a result, the water temperature is significantly reduced before it reaches the cold water basin at the bottom, where it is recirculated for further cooling applications.

Advantages of Induced Draft Counterflow Cooling Towers

✅ Superior Efficiency Compared to Other Cooling Tower Types – The counter flow design allows for more effective heat exchange than cross flow cooling towers.

✅ Rapid Cooling Performance – The increased surface area created by the PVC filler enhances cooling efficiency and accelerates temperature reduction.

✅ Ideal for High-Demand Cooling Systems – Suitable for power plants, industrial facilities, and large-scale refrigeration units.

✅ Energy-Saving Solution – While counter flow towers may have higher air pressure loss, their superior cooling efficiency helps reduce the overall energy consumption of cooling systems.

✅ Rapid Cooling Performance – The increased surface area created by the PVC filler enhances cooling efficiency and accelerates temperature reduction.

✅ Ideal for High-Demand Cooling Systems – Suitable for power plants, industrial facilities, and large-scale refrigeration units.

✅ Energy-Saving Solution – While counter flow towers may have higher air pressure loss, their superior cooling efficiency helps reduce the overall energy consumption of cooling systems.

The Induced Draft Counterflow Cooling Tower is the ideal choice for industries that require high-performance cooling solutions with long-term energy savings. If you are looking for a cooling tower that meets your specific operational needs, contact us today for expert consultation!

Material of Construction

| PART | Material |

| STRUCTURE | Made of hot dip galvanized steel. All parts are connected with galvanized bolts & nuts Tower walls are made of glass fiber reinforced plastic. |

| AIR INLET MESH | Made of PE plastic to prevent foreign material sucked into tower. |

| FAN DUCT | Made of glass fiber reinforced plastic (FRP) installed on top of the tower. Shape is cone to facilitate aerodynamic efficiency and reduce pressure loss. |

| MOTOR | Motor is to drive tower fan. Due to humid air stream, the motor has to be water and moisture proof type IP 55 rated motor is normally used for our standard tower model. Unless higher rating is required. |

| GEAR REDUCER | Big cooling tower always requires high airflow. Hence big fan blade and diameter are necessary. Fan has to be run at lower speed in order to reduce tip speed and noise. Speed reducer is needed. Gear reducer or V-belt pulley drive are generally two options available. Gear reducer will be longer life and less maintenance. However it will be more noisy than V-belt drive. |

| FAN | Made of aluminium alloy. Fan is to create airflow so that water will contact stream air at large. Axial flow fan is suitable since it can make high airflow. Good fan has to be high efficiency, less vibration, corrosion resistnace and safely operated. |

| MOTOR SUPPORT | Made of hot dip galvanized steel. It's to support motor and gear reducer to operate securely. It's installed on top of fan duct and be with fan guard to prevent danger of fan hit. |

| WATER BASIN | Made of fiber glass reinforced plastic. It will receive cooled water leaving from bottom of the filler. Cooled water will flow into auxilrary suction tank before it will be sucked and recirculated back for cooling machines and equipments. Basin should have enough volume so that water level will never lower than outlet at starting up and water will never over flow at stopping. |

| FILLER | Made of PVC plastic film and corrugated. Water will spreaded over filler. Corrugation will create thin film of water. The film enhances heat transfer between water and air stream. |

| DRIFT ELIMINATOR | Made of fiber glass reinforced plastic (FRP). It will prevent carrying over of small water droplet with air stream leaving the tower. It will minimize water drift loss. |